When it comes to buying footwear, whether it’s a pair of comfortable sneakers, durable work boots, or stylish high heels, one factor should always be at the forefront of your mind – safety and quality.

If there is an ISI Mark on footwear it means the footwear meets the standard guidelines and its quality is checked under the Bureau of Indian Standards, BIS.

In this blog, we will explain ISI Mark Certification for Footwear. It is very important for the manufacturers who are involved in the business of Footwear and are selling their products in the Indian Market.

What is ISI Mark Certification?

The ISI Mark guarantees that a product adheres to specific quality and safety standards set by the Bureau of Indian Standards (Standard body of Indian Govt.).

If it comes to footwear, the ISI Mark Certification ensures that the product has passed all the tests that are required and meets the necessary criteria for quality, safety, and performance.

Why ISI Mark Certification is Mandatory for Footwear

It is mandatory for all importers, manufacturers, and sellers of footwear to ensure that their products bear the ISI Mark. Importing, manufacturing, or selling footwear products that are under mandatory ISI Mark Certification are not allowed to sell in the Indian market without ISI Mark. It is the responsibility of manufacturers, importers, and sellers to maintain the quality of their products and ensure consumer safety.

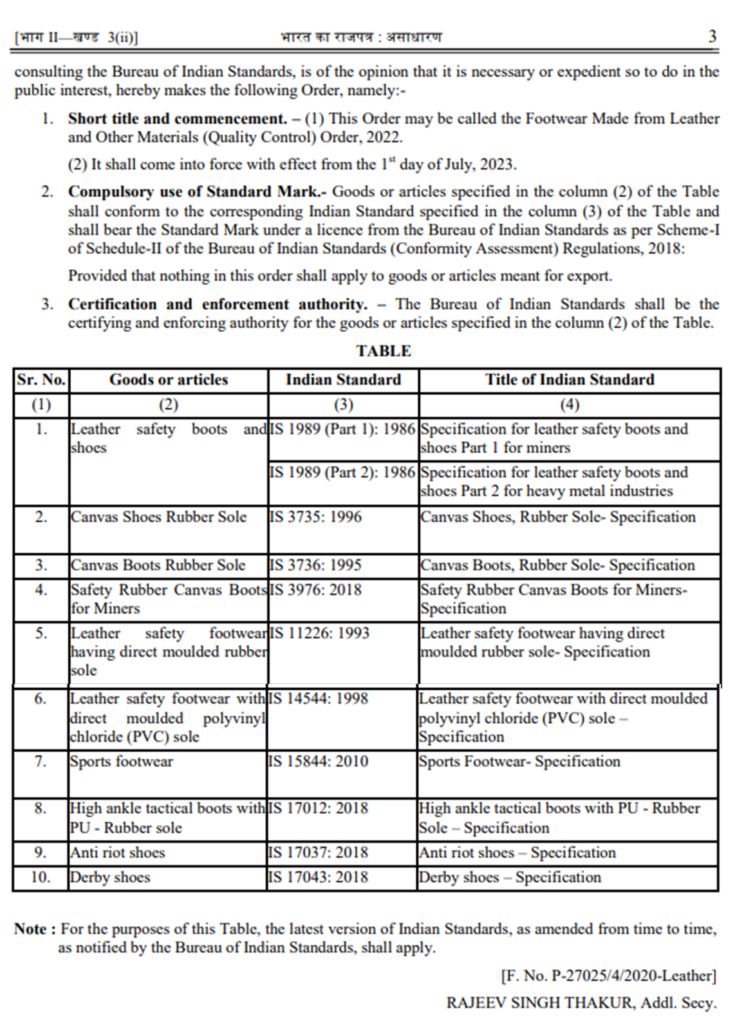

Quality Control Order

Indian Standards for Footwear

| IS 5557: 2004 | Industrial and protective rubber knee and ankle boots |

| IS 5557 (Part 2): 2018 | All rubber gum boots and ankle boots |

| IS 5676: 1995 | Moulded solid rubber soles and heels |

| IS 6664: 1992 | Rubber microcellular sheets for soles and heels |

| IS 6719: 1972 | Solid PVC soles and heels |

| IS 6721: 1972 | PVC sandal |

| IS 10702: 1992 | Rubber Hawai Chappal |

| IS 11544: 1986 | Slipper, rubber |

| IS 12254: 1993 | Polyvinyl chloride(PVC) industrial boots |

| IS 13893: 1994 | Polyurethane sole, semirigid |

| IS 13995: 1995 | Unlined moulded rubber boots |

| IS 16645: 2018 | Moulded plastics footwear- Lined or Unlined polyurethane boots for general industrial use |

| IS 16994: 2018 | Footwear for men and women for municipal scavenging work |

| IS 1989 (Part 1): 1986 | Leather safety boots and shoes for miners |

| IS 1989 (Part.2): 1986 | Leather safety boots and shoes for heavy metal industries |

| IS 3735: 1996 | Canvas Shoes Rubber Sole |

| IS 3736: 1995 | Canvas Boots Rubber Sole |

| IS 3976: 2018 | Safety Rubber Canvas Boots for Miners |

| IS 11226: 1993 | Leather safety footwear having direct moulded rubber sole |

| IS 14544: 1998 | Leather safety footwear with direct moulded polyvinyl chloride (PVC) sole |

| IS 15844: 2010 | Sports footwear |

| IS 17012: 2018 | High ankle tactical boots with PU – Rubber sole |

| IS 17037: 2018 | Antiriot shoes |

| IS 17043: 2018 | Derby shoes |

| IS 15298 (Part 2): 2016 | Personal protective equipment – Part 2 Safety Footwear |

| IS 15298 ( Part 3) : 2019 | Personal protective equipment – Part 3 Protective Footwear |

| IS 15298 (Part 4) : 2017 | Personal protective equipment – Part 4 Occupational Footwear |

ISI Mark Certification Process for Footwear

To see detailed information about the procedure for ISI Mark Certification visit ISI Mark Certification for Domestic Manufacturers.

ISI Mark Certification for Footwear under FMCS

The procedure for BIS ISI Mark Certification is different for Domestic Manufacturers and Foreign Manufacturers ISI Mark Certification for Foreign Manufacturers.

Required Documents for Footwear under Domestic Certification

- Factory Registration Documents & information

- Identity proof

- Manufacturing process flow chart

- Details of Authorized Signatory and other related documents

- Adequate testing facilities

- Quality Control Parameters and their records

- Laboratory testing report and other information as per BIS norm

- To see detailed information, you can visit here.

Required Documents for Footwear under FMCS ISI Mark

Due to the recent implementation of the BIS online application system for information gathering and management, the documentation aspect of the FMCS system for BIS is relatively uncomplicated.

- Proof of factory or company registration documentation.

- A flowchart detailing the manufacturing process.

- Information about on-site manufacturing capabilities and, if applicable, any outsourcing arrangements for manufacturing.

- Documentation demonstrating the presence of adequate testing infrastructure.

- Records of quality control (QC) metrics and their historical data.

All required documents, including the test and inspection schedule, annual labeling charge, laboratory product test report, and any other data complying with BIS standards, are accessible upon request from BIS. The complete list of documents is available upon inquiry.

To see detailed information, you can visit here.

Marking Guideline

Along with ISI Mark, the following details have to be given in the packaging of finished good

- Identification and classification

- Net mass of each package ( with serial number)

- Lot/batch number

- Transportation, handling, storage specifications, and consignment of proper cases.

Conclusion:

Mandatory BIS certification for Footwear is essential to ensure the quality and safety of these products. Obtaining BIS certification not only facilitates market access but also provides a competitive advantage and peace of mind to manufacturers and consumers alike.

It’s often beneficial to consult with BIS Consultants, such as INDUCE INDIA, to navigate the complex certification process effectively.

These consultants can provide guidance, and assistance with documentation, and help you understand the specific requirements of the ISI certification process, ensuring that your application is complete and meets all necessary criteria. For more information feel free to contact us call at +91-7503304082 or email at [email protected]